|

<< Click to Display Table of Contents >> Stock-Lead Time and Critical Time |

|

|

<< Click to Display Table of Contents >> Stock-Lead Time and Critical Time |

|

This is a guide to help with the inter-operation of Lead Time and the Inventory definitions used in the Material and Parts window.

There are two categories of interpreting the lead time and the critical time.

| A. | Lead time and critical time when creating a Part. (Fixed). |

| B. | Lead time and critical time using the Production or Client Order (dependent on current stock, orders and availability). |

How to establish lead time and critical time when creating, or changing parts.

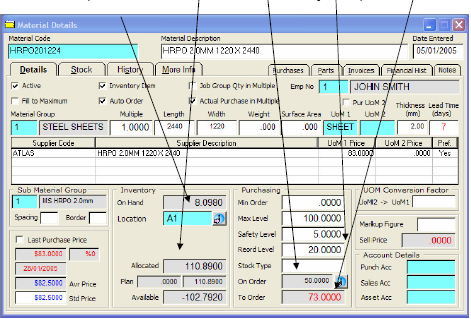

Each material and part has its own lead time. To mark a material or part as a stocked item two key fields need to be set correctly.

| 1. | The “Inventory” tick-box must be ticked. |

| 2. | The “Re-Order Qty” must be set greater than zero. ( >0 ) |

If Inventory and re-order quantity is greater than zero then the program assumes that production and purchasing has all item on-hand. If the lead time is 40 – 60 days then the re-order quantity must be sufficient enough to never run out of stock. Example – if usage is 1000 a month and the lead time is 90 days, the re-order quantity must be set at a minimum of 3000 + Safety stock level at 3500.

Example of Material:

8UNO-PORT = Inventory ticked and Re Order > 0 Then Lead Time = 0

8UNO-PORT = Inventory ticked and Re Order = 0 Then Lead Time = 60

To calculate the critical time for a Part –TS25-0333-ASSY

Lead Time for Part –TS25-0333-ASSY Production |

3 Days |

Material - 8UNO-PORT = Inventory ticked and Re Order > 0 |

0 Days |

Part BC250 = Inventory ticked and Re Order > 0 |

0 Days |

Material MTS25-0335 = Inventory ticked and Re Order = 0 |

6 Days |

Total Critical Time |

9 Days |

Lead Time for Part –TS25-0333-ASSY |

3 Days |

Material - 8UNO-PORT = Inventory ticked and Re Order = 0 |

60 Days |

Part BC250 = Inventory ticked and Re Order > 0 |

0 Days |

Material MTS25-0335 = Inventory ticked and Re Order = 0 |

6 Days |

Total Critical Time |

63 Days |

When creating the part and updating the critical time the system is ignoring current orders and on-hand figures. Only when entering the Client or Production Orders the system will check through and see what is available and will allocate and reserve Parts and Material. The order can now change the due date because the material or part will not arrive in time. This can be because my re-order level was not high enough or there is an unexpected big order entered into the system. Filling to Max (Parts and Material) is only an optional function and depends on the cost and usage.

Material (Not Stock Item)

If {INV_ITEM} = 1 and {MIN_STOCK} = 0 and {MAX_STOCK} = 0 and {REORDER_LEVEL} =0 Then Lead Time =60 days

Parts (Not Stocked Item)

If {INV_ITEM} = 1 AND {REORDER_LEVEL} = 0 Then Lead Time = 3 days

| a) | Maximum Inventory (fill to maximum optional) |

The planned maximum allowable inventory for an item based on its planned Lot size and target safety stock.

| b) | Safety Stock (not used in a calculation – indicator) |

A quantity of stock planned to be in inventory to protect against fluctuations in demand or supply.

| c) | Reorder Point |

A set inventory level where if the total stock on hand plus on order falls to or below that point. Action is taken to replenish the stock. The order point is normally calculated as forecasted usage during the replenishment lead plus safety stock.

| d) | Minimum Order Quantity |

An order quantity modifier applied after the lot size has been calculated that increases the order quantity to a re-established minimum.

| e) | To Order |

Time dependency – now, 7, 14, 30, 60 or 90 days.

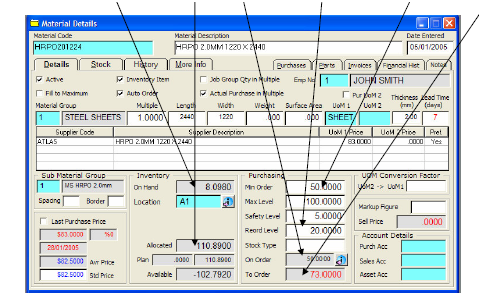

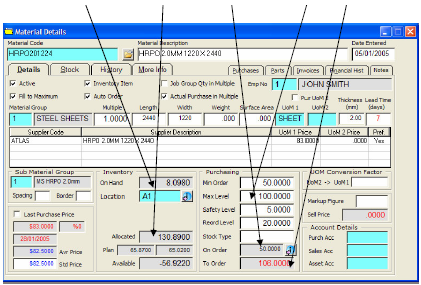

Formula for re-order with no Min-Order or Multiple Qty

= (Stk On Hand - Allocated + On Order + Reorder Qty + 1) = 73

Formula for Re-order with Min-Order Qty but no Multiple Qty

= (Stock On Hand - Allocation + On Order + Re-Order Qty + 1(>Min Order Qty) = 73

Formula for Re-order Fill to Maximum with Min Order Qty but no Multiple Qty

=(Stk On Hand - Allocation + On Order )= to Max 106

Last Revised: 23/03/2012 SJ